In the ever-evolving landscape of global construction and manufacturing, the demand for high-quality, efficient, and innovative steel processing equipment has reached new heights. Cutting-edge Chinese professional steel wire drawing machine and cold rolled ribbing machine are designed to revolutionize your production processes and meet the rigorous standards of modern projects.

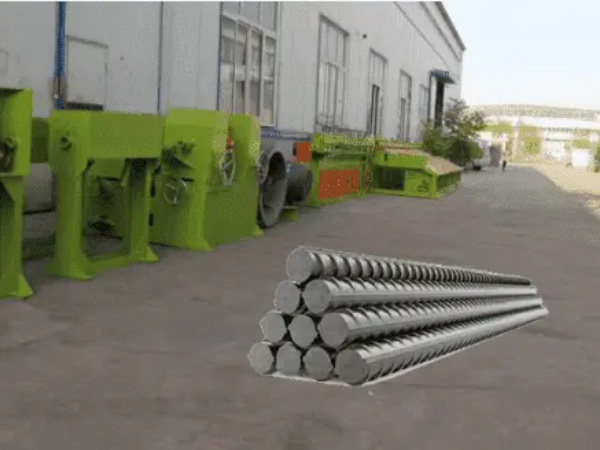

Unmatched Precision and Efficiency in Steel Wire Drawing

These steel wire drawing machines are a testament to advanced engineering and technological innovation. With the construction industry increasingly focusing on sustainable and durable infrastructure, the need for precisely drawn steel wires is crucial. Engineered to reduce the diameter of steel wires with exceptional accuracy, they enhance the strength and flexibility of the wires. This precision ensures that the final products, whether for reinforcing concrete in buildings or manufacturing high-tensile cables for bridges, meet and exceed industry specifications.

Equipped with state-of-the-art automation systems, the wire drawing machines significantly boost production efficiency. Automated controls allow for seamless adjustments in the drawing process, minimizing human error and increasing output. For instance, in large-scale manufacturing facilities, these machines can handle high volumes of steel wire continuously, reducing production time and costs. This efficiency not only improves your bottom line but also enables you to meet tight project deadlines, giving you a competitive edge in the market.

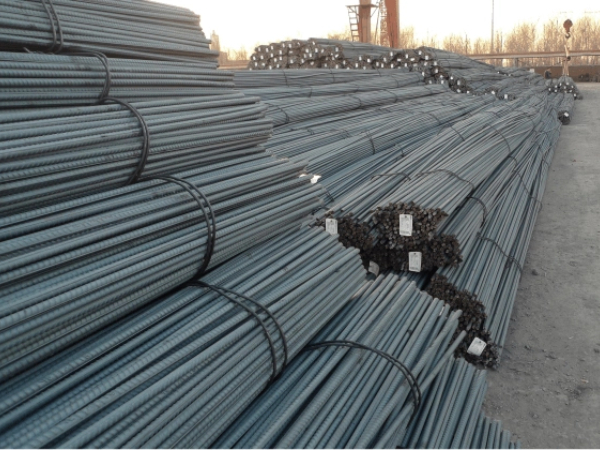

Transforming Steel with Cold Rolled Ribbing Technology

Cold rolled ribbing machines play a pivotal role in the construction and manufacturing sectors. Cold rolling is a process that deforms steel at room temperature, enhancing its mechanical properties. These ribbing machines are designed to create precisely defined ribs on the surface of steel bars, increasing the bond strength between the steel and concrete. This is particularly critical in building structures, where the integrity of the steel-concrete composite is essential for safety and durability.

In recent years, the construction industry has witnessed a surge in demand for precast concrete components and high-rise buildings. Cold rolled ribbed steel bars, produced using advanced machines, are ideal for these applications. They offer superior load-bearing capacity and resistance to cracking, making them a preferred choice for engineers and architects worldwide. Moreover, the energy-efficient nature of cold rolling aligns with the global push towards sustainable manufacturing practices, reducing the environmental impact of your production processes.

Customization and Global Support

A standout feature of these steel wire drawing and cold rolled ribbing machines from COREWIRE lies in their unparalleled customization capabilities. With a dedicated team of seasoned engineers and industry experts, COREWIRE understands that each project has distinct requirements. From the moment you engage with us, our experts will conduct in-depth consultations, analyzing your production goals, existing infrastructure, and budget constraints. Whether you need a machine with a specific production capacity to handle high-volume orders, a customized speed setting for intricate processing, or unique control features to integrate with your existing automation systems, we leverage our extensive technical know-how to tailor a solution that fits your needs like a glove.

In addition to our top-tier customized equipment, COREWIRE provides comprehensive global support that spans continents. Our experienced technicians, trained to handle a wide range of machinery complexities, offer end-to-end services including professional installation, regular maintenance, and in-depth operator training. No matter if you're setting up a new production line in North America, expanding operations in Europe, or maintaining equipment in Southeast Asia, our global network of 20+ service centers ensures that prompt assistance is always within reach. This robust support system minimizes downtime, keeps your operations running smoothly, and provides you with peace of mind, knowing that you have a reliable partner by your side throughout the lifecycle of your equipment.

Post time: Jun-20-2025