2021 Latest Design Double Layer Roll Forming Machine - Standing Seam Roll Forming Machine – COREWIRE Detail:

Steel Standing Seam Roll forming Machine is a color-coated steel plate that is cold-rolled into various wave-shaped pressed plates. It is suitable for industrial and civil buildings, warehouses, special buildings, roofs, walls and interior and exterior wall decoration of large-span steel structures. It has the characteristics of light weight, high strength, rich color, convenient and quick construction, anti-seismic, fireproof, rainproof, long life and maintenance-free. It has been widely used.

Introduction

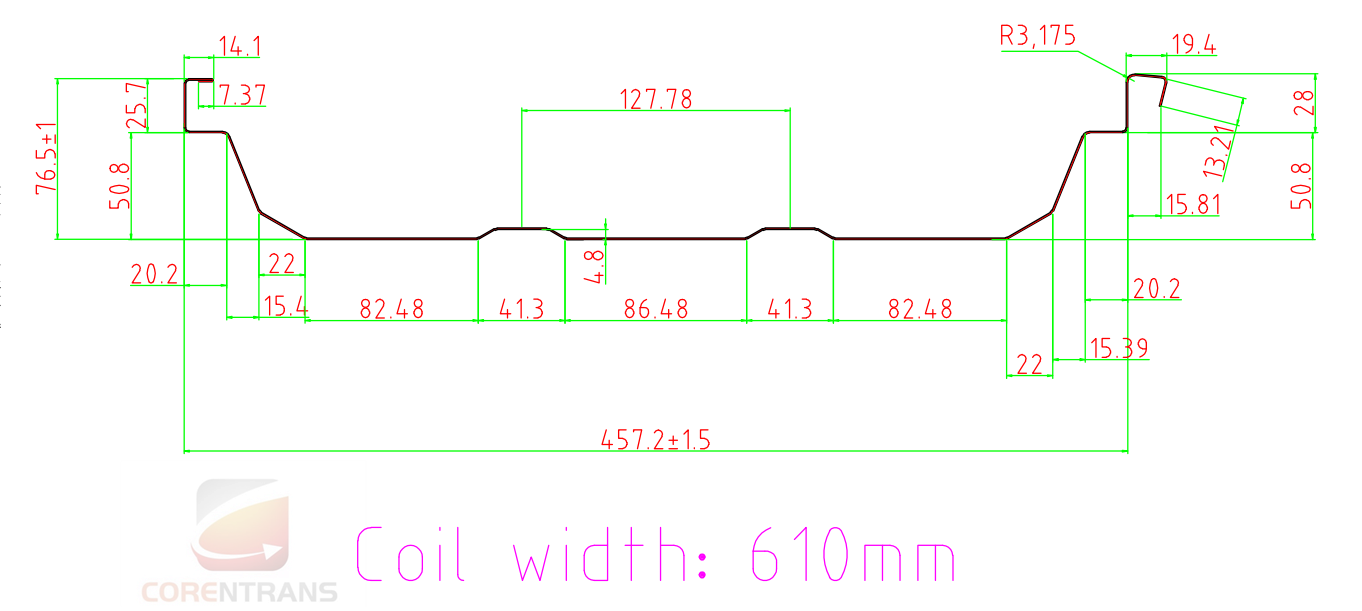

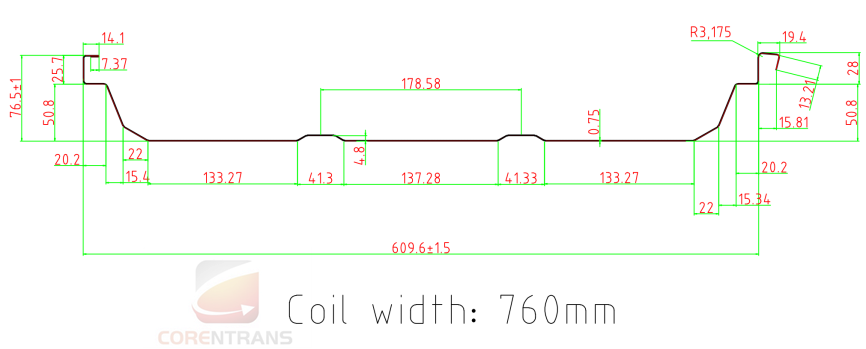

Profile drawing:

| No. | Specification of the material | |

| 1 | Suitable Material | PPGI 345Mpa |

| 2 | Width of the raw material | 610mm and 760mm |

| 3 | Thickness | 0.5-0.7mm |

Introduction of product operation steps

3T manual Un-coiler—Feeding&ribs—Cutting—Roll Forming—out table

Applications

Standing seam roof panel; Standing seam roof sheet; metal roofing sheet; steel roofing sheet; metal roof panel; steel roof panel; metal roof; steel roof; metal roof wall panel; steel roof wall panel;

Product parameters

|

No |

Item | Description |

|

1 |

Machine structure | Wire-electrode cutting frame |

|

2 |

Total power | Motor power-7.5kw Siemens Hydraulic power-5.5kw Siemens |

|

3 |

Roller stations | About 12 stations |

|

4 |

Productivity | 0-20m/min |

|

5 |

Drive system | By chain |

|

6 |

Diameter of shaft | ¢70mm solid shaft |

|

7 |

Voltage | 415V 50Hz 3phases (Customized) |

Related products

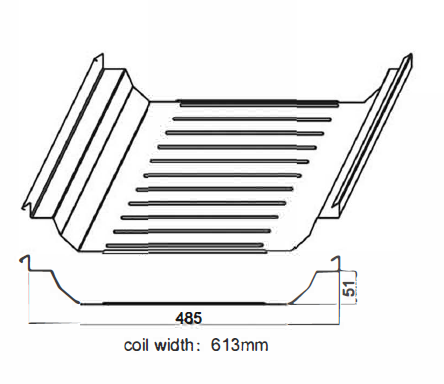

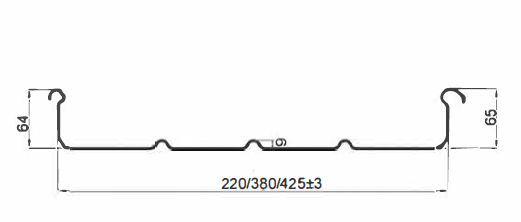

Product detail pictures:

Related Product Guide:

As for competitive selling prices, we believe that you will be searching far and wide for anything that can beat us. We will state with absolute certainty that for such excellent at such charges we are the lowest around for 2021 Latest Design Double Layer Roll Forming Machine - Standing Seam Roll Forming Machine – COREWIRE, The product will supply to all over the world, such as: Serbia, Sevilla, Paris, We set a strict quality control system. We have return and exchange policy, and you can exchange within 7 days after receive the wigs if it is in new station and we service repairing free for our products. Please feel free to contact us for further information if you have any questions. We are glad to work for every client.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.

-

OEM/ODM Supplier Welded Tube Mill - High Frequ...

-

High reputation Roofing Wall Panel Roll Forming...

-

Personlized Products Pc Steel Wire Stable Produ...

-

China New Product Wire Rods Surface Pre-Treatin...

-

Factory source Iron Nail Making - Straight Wir...

-

Low price for Hf Welded Tube Mill - Automatic ...