Bottom price Roof Sheet Roll Forming Machine - Guard Rail Roll Forming Machine – COREWIRE Detail:

Guard rail roll forming machine is used to produce guard rails or crash barriers. Hot rolled, galvanized or other steel sheet and coil is suitable roll forming materials for this machine. This machine is mainly made up of loading coil car, exit looping kit, roll former with tooling, automatic stacking device, flying cut-off machine, servo roll feeder, leveler, loading coil car, etc. The finished products are widely used on highway, expressway and other public places to prevent different kinds of accidents and improve safety. They can also be used as fence for livestock farms and other places.

Features

1. This production line can be automatically run by inputting some data (like products length and batches) to the PLC control system.

2. Very strong base frame is configured to avoid vibration.

3. All the rollers have been processed by CNC lathe and polished on the surface to guarantee the accuracy.

4. The rollers have gone through hardened treatment to guarantee long lifespan.

5. We can also design the crash barrier roll forming machine according to customer’s requirement.

Forming Processing

Hydraulic decoiler – Leveling – Feeding – Punching – Conveyor – Roll forming – Auto Stacker

Introduction

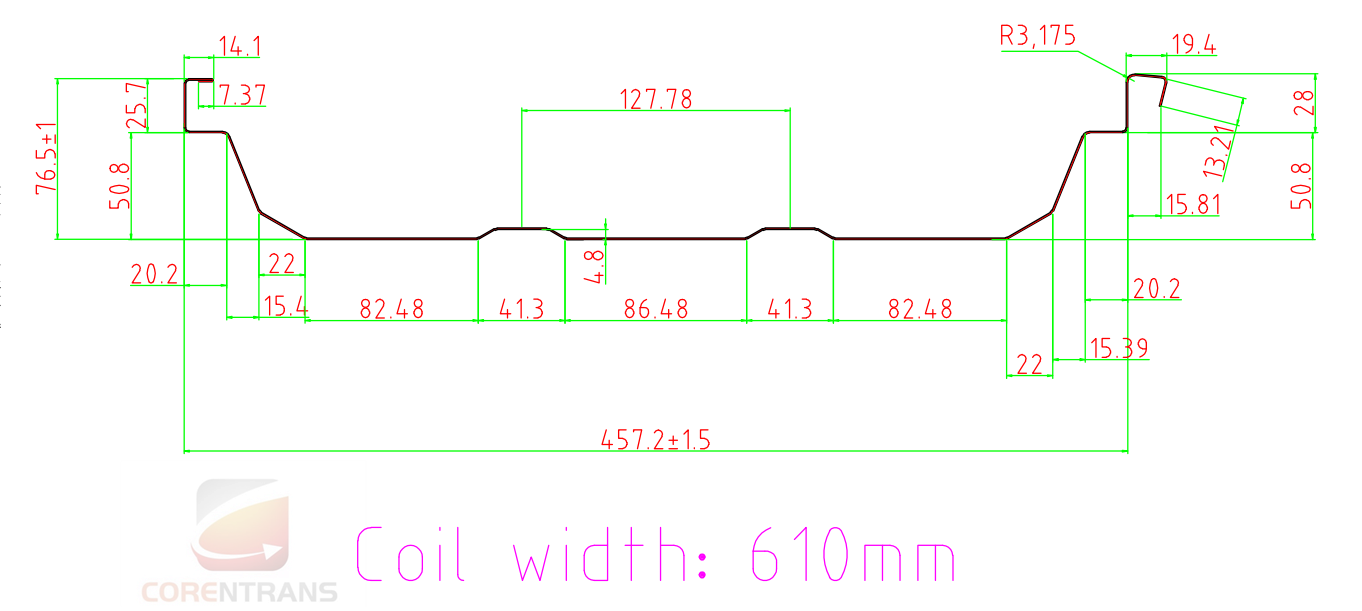

Profile drawing:

| No. | Specification of the material | |

| 1 | Suitable Material | PPGI 345Mpa |

| 2 | Width of the raw material | 610mm and 760mm |

| 3 | Thickness | 0.5-0.7mm |

Product parameters

|

No |

Item | Description |

|

1 |

Machine structure | Wire-electrode cutting frame |

|

2 |

Total power | Motor power-7.5kw Siemens Hydraulic power-5.5kw Siemens |

|

3 |

Roller stations | About 12 stations |

|

4 |

Productivity | 0-20m/min |

|

5 |

Drive system | By chain |

|

6 |

Diameter of shaft | ¢70mm solid shaft |

|

7 |

Voltage | 415V 50Hz 3phases (Customized) |

Related products

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for Bottom price Roof Sheet Roll Forming Machine - Guard Rail Roll Forming Machine – COREWIRE, The product will supply to all over the world, such as: Los Angeles, Florida, Jakarta, To win customers' confidence, Best Source has set up a strong sales and after-sales team to deliver the best product and service. Best Source abides by the idea of "Grow with customer" and philosophy of "Customer-oriented" to achieve cooperation of mutual trust and benefit. Best Source will always stand ready to cooperate with you. Let's grow together!

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!

-

100% Original High Frequency Tube Mill - Autom...

-

China Supplier Steel Door Frame Roll Forming Ma...

-

Newly Arrival Coil Cut To Length Line - Automa...

-

OEM Customized Portable Standing Seam Roll Form...

-

Manufacturer of Slitting Line - Cut to length ...

-

Ordinary Discount Automatic Saw Blade Grinding ...