factory Outlets for Roofing Sheet Roll Forming Machine - High Speed Roofing Panel Roll Forming Machine – COREWIRE Detail:

Introduction of product operation steps

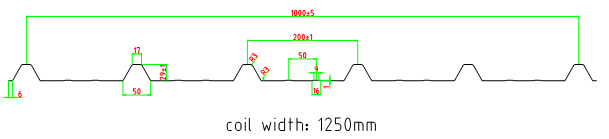

Profile drawing:

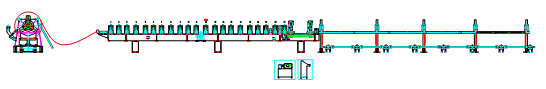

The chart of process flow:

10T Hydraulic Uncoiler—Roll Forming—Track cutting—Auto stacker

Product parameters

| 1 | Coil width | 1250mm |

| 2 | Rolling Speed | 0-35m/min |

| 3 | Rolling Thickness | 0.3-0.8mm |

| 4 | Control System | PLC (Panasonic) as list in the note |

| 5 | Un Coiler | 5T hydraulic de-coiler |

| 6 | Roller Stations | 20 stations |

| 7 | Roller Material | ASTM1045 chrome plated surface with chrome |

| 8 | Shaft Material and DIA | ¢76mm material:45# with quenching and tempering |

| 9 | Post track cutting | The main machine won’t stop when cutting, 2.9kw servo motor |

| 10 | Maim Motor Power | 15kw |

| 11 | Hydraulic Station Power | 5.5kw with storage tank and air cooling system |

| 12 | Hydraulic Pressure | 12-16Mpa adjustable |

| 13 | Material Of Cutting | CR12with heat treatment |

| 14 | Structure Of The Stations | Iron cast |

| 15 | Tolerance | 3m+-1.5mm |

| 16 | Electric Source | 380V, 50HZ,3 phaseAccording to customer’s require |

| 17 | Way Of Drive | By gear box |

Related products

Packaging & Delivery

Packaging Details:

Roofing Panel Roll Forming Machine

1. The machine is nude loaded in the container

2. The electric controlling box is packed by protect film

3. All the spare parts are put in the wooden box

Product detail pictures:

Related Product Guide:

carry on to boost, to guarantee products excellent in line with market and consumer standard specifications. Our enterprise has a quality assurance system are actually established for factory Outlets for Roofing Sheet Roll Forming Machine - High Speed Roofing Panel Roll Forming Machine – COREWIRE, The product will supply to all over the world, such as: Guatemala, Luxembourg, Casablanca, Our advantages are our innovation, flexibility and reliability which have been built during last 20 years. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade products in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!

-

Wholesale Price China Steel Tube Mill - Automa...

-

100% Original Automatic Chain Link Fencing Mach...

-

2021 High quality Purlin Forming Machine - Met...

-

Hot New Products Tube Mill - High Frequency ER...

-

Hot Sale for Cap Nail Machine - Electrode Rods...

-

New Arrival China Electrode Rods E6013 - High ...