Factory Price For Steel Frame Roll Forming Machine - High Speed Roofing Panel Roll Forming Machine – COREWIRE Detail:

Introduction of product operation steps

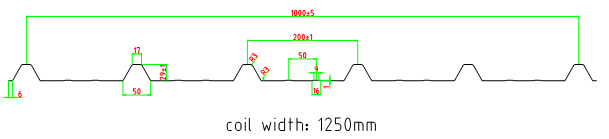

Profile drawing:

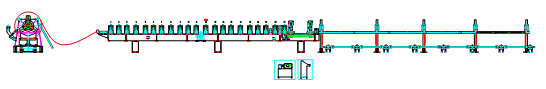

The chart of process flow:

10T Hydraulic Uncoiler—Roll Forming—Track cutting—Auto stacker

Product parameters

| 1 | Coil width | 1250mm |

| 2 | Rolling Speed | 0-35m/min |

| 3 | Rolling Thickness | 0.3-0.8mm |

| 4 | Control System | PLC (Panasonic) as list in the note |

| 5 | Un Coiler | 5T hydraulic de-coiler |

| 6 | Roller Stations | 20 stations |

| 7 | Roller Material | ASTM1045 chrome plated surface with chrome |

| 8 | Shaft Material and DIA | ¢76mm material:45# with quenching and tempering |

| 9 | Post track cutting | The main machine won’t stop when cutting, 2.9kw servo motor |

| 10 | Maim Motor Power | 15kw |

| 11 | Hydraulic Station Power | 5.5kw with storage tank and air cooling system |

| 12 | Hydraulic Pressure | 12-16Mpa adjustable |

| 13 | Material Of Cutting | CR12with heat treatment |

| 14 | Structure Of The Stations | Iron cast |

| 15 | Tolerance | 3m+-1.5mm |

| 16 | Electric Source | 380V, 50HZ,3 phaseAccording to customer’s require |

| 17 | Way Of Drive | By gear box |

Related products

Packaging & Delivery

Packaging Details:

Roofing Panel Roll Forming Machine

1. The machine is nude loaded in the container

2. The electric controlling box is packed by protect film

3. All the spare parts are put in the wooden box

Product detail pictures:

Related Product Guide:

It can be a great way to enhance our solutions and service. Our mission would be to build inventive products to consumers with a superior working experience for Factory Price For Steel Frame Roll Forming Machine - High Speed Roofing Panel Roll Forming Machine – COREWIRE, The product will supply to all over the world, such as: Jakarta, Bulgaria, Belgium, We have top engineers in these industries and an efficient team in the research. What is more, now we have our own archives mouths and markets in China at low cost. Therefore, we can meet different inquiries from different clients. Remember to find our website to check more information from our merchandise.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.

-

High definition Erw Tube Mill Machine - Automa...

-

2021 wholesale price Wire Drawing Machine - Co...

-

Top Quality Wire Drawing Machine Process - Str...

-

Hot Selling for Slitting Production Line - sta...

-

Massive Selection for Automatic Roll Forming Ma...

-

Europe style for Uncoiling Slitting Recoiling L...