Factory wholesale Steel Roof Panel Press - Guard Rail Roll Forming Machine – COREWIRE Detail:

Guard rail roll forming machine is used to produce guard rails or crash barriers. Hot rolled, galvanized or other steel sheet and coil is suitable roll forming materials for this machine. This machine is mainly made up of loading coil car, exit looping kit, roll former with tooling, automatic stacking device, flying cut-off machine, servo roll feeder, leveler, loading coil car, etc. The finished products are widely used on highway, expressway and other public places to prevent different kinds of accidents and improve safety. They can also be used as fence for livestock farms and other places.

Features

1. This production line can be automatically run by inputting some data (like products length and batches) to the PLC control system.

2. Very strong base frame is configured to avoid vibration.

3. All the rollers have been processed by CNC lathe and polished on the surface to guarantee the accuracy.

4. The rollers have gone through hardened treatment to guarantee long lifespan.

5. We can also design the crash barrier roll forming machine according to customer’s requirement.

Forming Processing

Hydraulic decoiler – Leveling – Feeding – Punching – Conveyor – Roll forming – Auto Stacker

Introduction

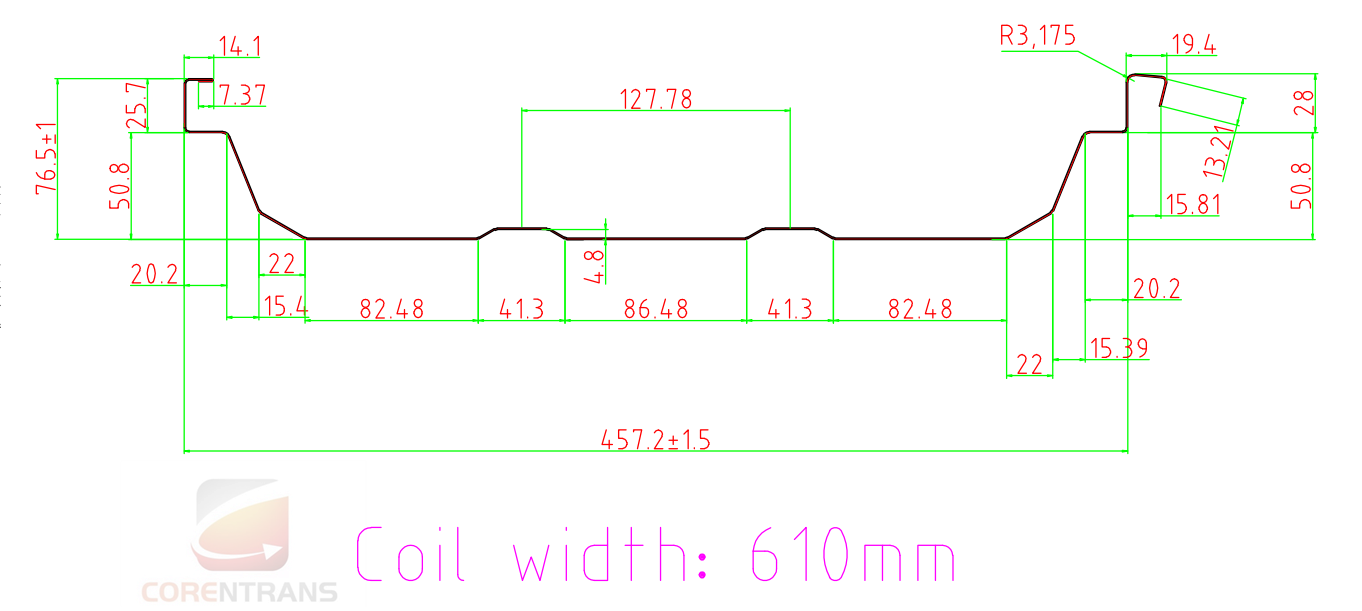

Profile drawing:

| No. | Specification of the material | |

| 1 | Suitable Material | PPGI 345Mpa |

| 2 | Width of the raw material | 610mm and 760mm |

| 3 | Thickness | 0.5-0.7mm |

Product parameters

|

No |

Item | Description |

|

1 |

Machine structure | Wire-electrode cutting frame |

|

2 |

Total power | Motor power-7.5kw Siemens Hydraulic power-5.5kw Siemens |

|

3 |

Roller stations | About 12 stations |

|

4 |

Productivity | 0-20m/min |

|

5 |

Drive system | By chain |

|

6 |

Diameter of shaft | ¢70mm solid shaft |

|

7 |

Voltage | 415V 50Hz 3phases (Customized) |

Related products

Product detail pictures:

Related Product Guide:

"Quality first, Honesty as base, Sincere service and mutual profit" is our idea, in order to develop continuously and pursue the excellence for Factory wholesale Steel Roof Panel Press - Guard Rail Roll Forming Machine – COREWIRE, The product will supply to all over the world, such as: Macedonia, Kenya, Singapore, Since always, we adhering to the "open and fair, share to get, the pursuit of excellence, and creation of value"values, adhere to the"integrity and efficient, trade-oriented, best way , best valve" business philosophy. Together with our all over the world have branches and partners to develop new business areas, maximum common values. We sincerely welcome and together we share in global resources, opening up new career together with the chapter.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.

-

China Cheap price Straight Type Wire Drawing Ma...

-

2021 China New Design Z Purlin - High Speed Ro...

-

New Arrival China Cz Interchangeable - CWE-160...

-

Best Price for Nail Making Factory - High Spee...

-

Special Price for Gutter Roll Forming Machine -...

-

Lowest Price for Motorway Guardrail Roll Formin...