Good quality Welding Rod Production Line - Cold Rolled Ribbing Machine – COREWIRE Detail:

Product introduction:

|

Product |

Pictures |

Quantity (Set) |

Remark |

| Flying shear cutting machine |

1 |

17KWCNC servo flying shear motor, synchronous motor | |

| Hydraulic Spooler Take-up |

1 |

||

| Control Cabinet |

1 |

Digital control | |

| Straightening Machine |

1 |

Multi-wheel straightening machine to straighten finished products.Multi-wheel small diameter and high frequency straightening method to straighten the finished product.Number of straightening wheels: 24 | |

| Rack |

1 |

||

| Pneumatic Packing Machine |

1 |

Packing Strip width: 14/16mmStrip thickness: 0.38-0.8mmWeight: 5KGPneumatic pressure: 0.42-0.6Mpa

Tension speed: 0.5m/min |

|

| Butt Welding machine |

1 |

Motor power: 10KWFunction: Connecting steel bars together |

Product advantages:

1. Cold Rolled Ribbing Machine is the most developed machine with compact structure, small footprint.

2. Cold Rolled Ribbing Machine is featured by small size, short-distance recycling winding and high capacity.

3. Gearbox Reducer of cold rolling ribbed steel bar is large torque, low noise, durable.

4. Advanced frequency inverter technology can save 40-60% power.

5. Pure steel mill foundry and no cracking.

Product Applications:

Cold rolled ribbed steel bars have been widely used in construction projects, highways, airports, municipalities, water and electricity pipelines. The high strength of steel can save construction steel and reduce the cost of construction.

Product Parameters

| Item | 20000T | 30000T | 50000T |

| Maximum steel bar process diameter | φ6 -13.5 mm | φ6.5 -12 mm | φ6 -16 mm |

| Diameter of finished steel bar | φ5 -12 mm | φ5.5 -11 mm | Φ6 -14mm |

| Straightening speed | 120 m/min | 180 m/min | 190 m/min |

| Shearing mode | Frequency conversion flying shear | Servo flying shear | Servo flying shear |

| Main motor power | 55-75 KW | 110 KW | 130-160 KW |

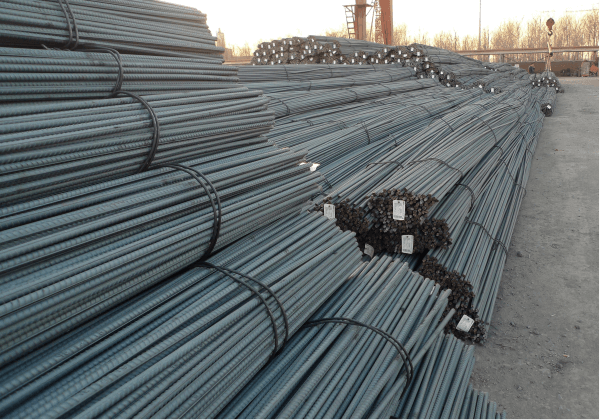

Product detail pictures:

Related Product Guide:

We often stay with the principle "Quality Very first, Prestige Supreme". We have been fully committed to supplying our consumers with competitively priced high-quality goods, prompt delivery and skilled provider for Good quality Welding Rod Production Line - Cold Rolled Ribbing Machine – COREWIRE, The product will supply to all over the world, such as: Bulgaria, Macedonia, Toronto, As a well educated, innovative and energetic staff,we are responsible for all elements of the research, design, manufacturing, sales and distribution. With studying and developing new techniques,we are not only following but also leading the fashion industry. We listen attentively to the feedback from our customers and provide instant communication. You will instantly feel our expertise and attentive service.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!

-

Best quality Corrugated Roll Forming Machine -...

-

Short Lead Time for Downspout Roll Forming Mach...

-

Popular Design for Wire Spoiler - High Speed B...

-

High definition Corrugated Iron Sheet Roll Form...

-

Best-Selling Wire Coils Take Up - High Quality...

-

Factory Price For Automatic Steel Sheet Slittin...