High reputation Roofing Wall Panel Roll Forming Machine - Corrugated Roll Forming Machine – COREWIRE Detail:

Main Character

♦ Completely automatic cutting.

♦ Easy installation, good performance.

♦ Low noise, high efficiency.

Introduction of product operation steps

Hydraulic de-coiler → roll forming → hydraulic punching (2sets) → cutting →curing machine → product

Product introduction

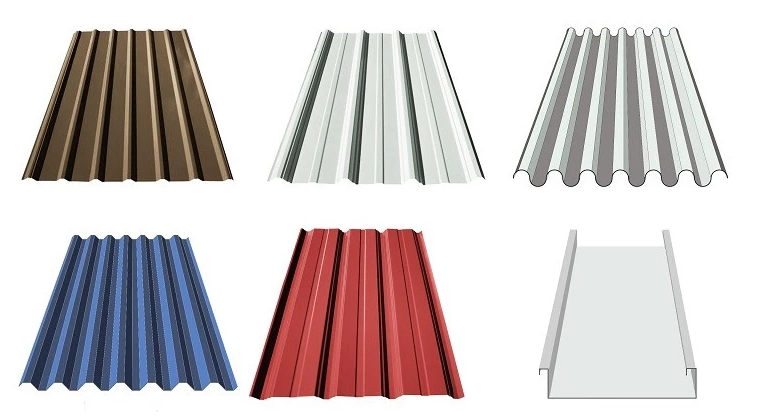

This Corrugated roll forming machine can produce corrugated metal tiles for industrial and civil buildings, warehouses, special buildings, large span steel roofs, house walls and exterior decoration, etc. It also includes some villages, supermarkets, hotels, exhibition halls, home buildings, shopping mall shutters and other buildings. Corrugated roll forming machine, roofing tile surface is very smooth and beautiful, the roof is not scratched. It has beautiful, external, classical appearance and elegant taste. We supply the best machine for our customer.

We have dozens of profile model machines for this series of molding, and we can design various profiles and accessories according to customers’ requirements.

Product parameters

| No | Item | Description |

| 1 | Material thickness | 0.3-0.8mm/ 2-4mm |

| 2 | Forming speed | 12-15m/min / 25-30m/min /15m/min |

| 3 | Roll station | 18 stations |

| 4 | Main power | 5.5KW/ 7.5KW/ 37KW |

| 5 | Hydraulic power | 3KW/ 7.5KW |

| 6 | Control system | PLC Panasonic |

| 7 | Drive | By Chain/ by gear box |

Main Technical Specification

| Material thickness: 0.3-0.8mm | Material thickness: 0.3-0.8mm | Material thickness:2-4mm |

| Working speed: 12-15m/min | Working speed: 25-30m/min | Working speed: 15m/min |

| Roll station: 18 stations (depend on the profile) | Roll station: 18 stations (depend on the profile) | Roll station: 18 stations (depend on the profile) |

| Main power: 5.5KW | Main power: 7.5KW | Main power: 37KW |

| Hydraulic power: 3KW | Hydraulic power: 3KW | Hydraulic power: 7.5KW |

| Control system: PLC Panasonic | Control system: PLC Panasonic | Control system: PLC Panasonic |

| Drive: by chain | Drive: by chain | Drive: by gear box |

Related products

Product detail pictures:

Related Product Guide:

It really is a good way to further improve our goods and service. Our mission would be to acquire inventive items to buyers with a very good encounter for High reputation Roofing Wall Panel Roll Forming Machine - Corrugated Roll Forming Machine – COREWIRE, The product will supply to all over the world, such as: Ghana, Curacao, Brunei, Our technical expertise, customer-friendly service, and specialized merchandise make us/company name the first choice of customers and vendors. We've been looking for your inquiry. Let's set up the cooperation right now!

This supplier offers high quality but low price products, it is really a nice manufacturer and business partner.