Hot Sale for Corrugated Roll Former - High Speed Roofing Panel Roll Forming Machine – COREWIRE Detail:

Introduction of product operation steps

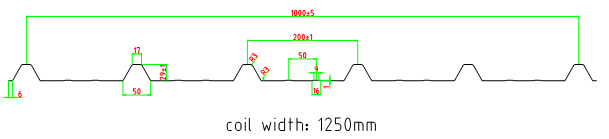

Profile drawing:

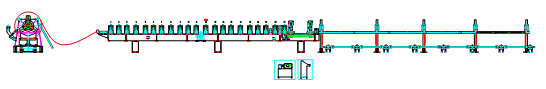

The chart of process flow:

10T Hydraulic Uncoiler—Roll Forming—Track cutting—Auto stacker

Product parameters

| 1 | Coil width | 1250mm |

| 2 | Rolling Speed | 0-35m/min |

| 3 | Rolling Thickness | 0.3-0.8mm |

| 4 | Control System | PLC (Panasonic) as list in the note |

| 5 | Un Coiler | 5T hydraulic de-coiler |

| 6 | Roller Stations | 20 stations |

| 7 | Roller Material | ASTM1045 chrome plated surface with chrome |

| 8 | Shaft Material and DIA | ¢76mm material:45# with quenching and tempering |

| 9 | Post track cutting | The main machine won’t stop when cutting, 2.9kw servo motor |

| 10 | Maim Motor Power | 15kw |

| 11 | Hydraulic Station Power | 5.5kw with storage tank and air cooling system |

| 12 | Hydraulic Pressure | 12-16Mpa adjustable |

| 13 | Material Of Cutting | CR12with heat treatment |

| 14 | Structure Of The Stations | Iron cast |

| 15 | Tolerance | 3m+-1.5mm |

| 16 | Electric Source | 380V, 50HZ,3 phaseAccording to customer’s require |

| 17 | Way Of Drive | By gear box |

Related products

Packaging & Delivery

Packaging Details:

Roofing Panel Roll Forming Machine

1. The machine is nude loaded in the container

2. The electric controlling box is packed by protect film

3. All the spare parts are put in the wooden box

Product detail pictures:

Related Product Guide:

abide by the contract", conforms to the market requirement, joins during the market competition by its superior quality also as provides extra comprehensive and exceptional service for consumers to let them turn into significant winner. The pursue of the business, is definitely the clients' gratification for Hot Sale for Corrugated Roll Former - High Speed Roofing Panel Roll Forming Machine – COREWIRE, The product will supply to all over the world, such as: Zimbabwe, Mumbai, Las Vegas, Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound solutions with good logistics service and economical cost. Depending on this, our solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

We are old friends, the company's product quality has been always very good and this time the price is also very cheap.

-

Low price for Hf Welded Tube Mill - stainless-...

-

OEM Customized Best Nail Making Machine - Stra...

-

China Factory for Steel Slitter - Cut to lengt...

-

China Cheap price Round Tube Machine - stainle...

-

2021 High quality Tube Mill Tooling - Automati...

-

Bottom price High Frequency Welding Tube Mill -...