OEM Customized Stainless Steel Tube Mills - High Frequency ERW Tube & Pipe Mill Machine – COREWIRE Detail:

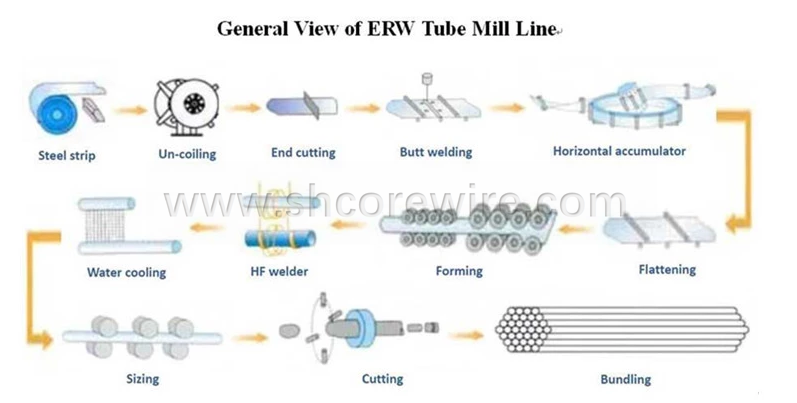

Flow Chart

{Steel strips} →→Double-head un-coiler →→Strip-head Shearer & TIG Butt welder station →→ HORIZONTAL SPIRAL ACCUMULATOR →→Forming M/C (Main driving unit ① +Flattening Entry unit + Breakdown zone + Fin pass zone + Seam guide unit + High-frequency induction welding system + Squeeze welding roller unit + Outside scarfing unit + Zinc spray patching system for welded seam(optional) + Horizontal ironing stand) + Emulsion water Cooling section + Sizing M/C (Main driving unit ② +Sizing zone + Speed testing unit + Turk straightener + Vertical pull-out frame) →→ NC Cold flying saw under computer control→→Run-out table →→{Stacking & packing section (optional)

Product introduction

1. Accumulating more than 20 years of professional manufacturing experience, SHANGHAI COREWIRE INDUSTRY CO., LTD. Specialized in supplying TM-12~273 ERW tube mill machine efforts quality improvement and technological researching.

2. Meanwhile, the R&D center featured The ERW tube mill with high-strength design, material selection, precision machining, stable operation, and energy conservation.

Application

The products are mainly pipes and tubes used in petroleum, petrochemical, construction, shipbuilding, military, electric power, mining, coal, machinery manufacturing industries.

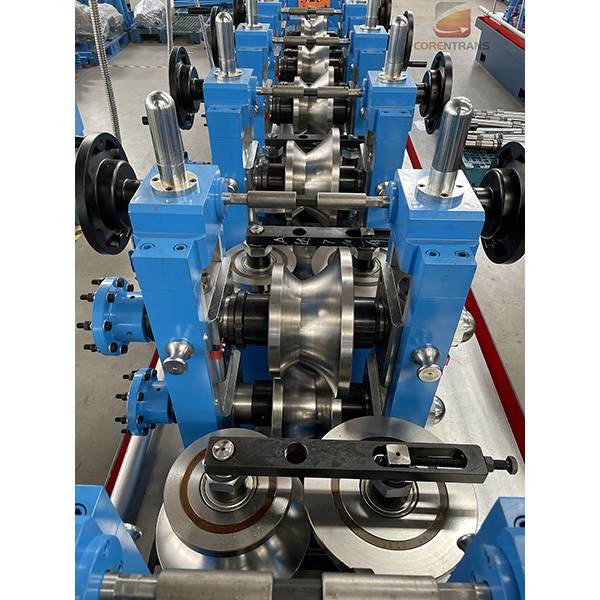

Customized Production Line

This TM-32 ERW Tube & Pipe Mill, complete with un-coiler & strip-head shearer & butt welder station & forming mill & sizing mill & cold flying saw & conveyor table & stacking & packing machine. The optimized design, high-quality material selection, and strict heat treatment process guarantee the high precision, wear-resisting, and long life of the roller.

ERW Specification

|

Model |

Tube O.D |

Wall Thickness |

Square/Rectangle |

Wall Thickness |

Speed |

Main motor |

H.F.Welder |

|

TM-12 |

φ4~φ12 |

0.2~0.5 |

// |

// |

30~120 |

15 |

100 |

|

TM-16 |

φ6~φ16 |

0.2~0.8 |

// |

// |

30~120 |

22 |

100 |

|

TM-20 |

φ7~φ20 |

0.2~1.0 |

// |

// |

30~120 |

30 |

100 |

|

TM-25 |

φ9~φ25.4 |

0.25~1.2 |

// |

// |

30~120 |

37(or22*2) |

100 |

|

TM-32 |

φ10~φ32 |

0.25~1.5 |

8*8~25.4*25.4 |

0.25~1.2 |

30~120 |

45(or 30*2) |

100 |

|

TM-32z |

0.5~2.0 |

0.5~1.5 |

30~100 |

55(or 37*2) |

100 |

||

|

TM-40 |

φ12.7~φ40 |

0.3~1.8 |

10*10~31.8*31.8 |

0.3~1.5 |

30~110 |

75 |

150 |

|

TM-40z |

0.6~2.0 |

0.6~1.5 |

30~100 |

45*2 |

150 |

||

|

TM-50q |

φ16~φ50.8 |

0.4~1.5 |

12.7*12.7~40*40 |

0.4~1.2 |

30~110 |

90 |

150 |

|

TM-50 |

0.5~2.0 |

0.5~1.5 |

30~90 |

45*2(or 110) |

200 |

||

|

TM-50z |

0.7~2.5 |

0.7~2.0 |

30~80 |

55*2 |

200 |

||

|

TM-63q |

φ19.05~φ63.5 |

0.6~2.0 |

15*15~50*50 |

0.6~1.5 |

30~90 |

132(or 55*2) |

150 |

|

TM-63 |

0.7~3.0 |

0.7~2.5 |

30~80 |

75*2(or 132) |

200 |

||

|

TM-63z |

0.8~3.5 |

0.8~3.0 |

20~70 |

90*2 |

200 |

||

|

TM-76q |

φ25.4~φ76.2 |

0.8~2.5 |

20*20~60*60 |

0.8~2.0 |

30~90 |

160(or 75*2) |

200 |

|

TM-76 |

0.8~3.5 |

0.8~3.0 |

30~80 |

90*2 |

250 |

||

|

TM-76z |

0.8~4.0 |

0.8~3.5 |

20~70 |

300 |

|||

|

TM-90q |

φ30~φ90 |

0.8~3.0 |

25*25~70*70 |

0.8~2.5 |

30~90 |

180(or 90*2) |

250 |

|

TM-90 |

0.8~3.5 |

0.8~3.0 |

30~80 |

110*2 |

250 |

||

|

TM-90z |

1.0~4.0 |

1.0~3.5 |

20~70 |

300 |

|

Model |

Tube O.D |

Wall Thickness |

Square/Rectangle |

Wall Thickness |

Speed |

Main motor |

H.F.Welder |

|

TM-100q |

φ31.8~φ101.6 |

1.0~3.0 |

25*25~80*80 |

1.0~2.5 |

30~90 |

200(or 110*2) |

250 |

|

TM-100 |

1.0~3.75 |

1.0~3.25 |

30~80 |

110*2 |

300 |

||

|

TM-100z |

1.0~4.25 |

1.0~3.5 |

20~70 |

132*2 |

300 |

||

|

TM-114q |

φ35~φ114.3 |

1.0~3.0 |

30*30~90*90 |

1.0~2.5 |

20~80 |

110*2 |

300 |

|

TM-114 |

1.2~4.5 |

1.2~4.0 |

20~70 |

132*2 |

350 |

||

|

TM-114z |

φ40~φ114.3 |

1.2~5.0 |

1.2~4.5 |

15~60 |

350 |

||

|

TM-127q |

φ40~φ127 |

1.2~3.5 |

40*40~100*100 |

1.2~3.0 |

20~70 |

132*2 |

350 |

|

TM-127 |

1.5~5.0 |

1.5~4.5 |

15~60 |

160*2 |

400 |

||

|

TM-127z |

φ50~φ127 |

1.5~5.5 |

1.5~5.0 |

10~45 |

160*2 |

400 |

|

|

TM-140q |

φ50~φ141.3 |

1.2~4.0 |

50*50~110*100 |

1.2~3.5 |

15~60 |

160*2 |

400 |

|

TM-140 |

1.5~5.5 |

1.5~5.0 |

10~50 |

180*2 |

400 |

||

|

TM-140z |

φ60~φ141.3 |

2.0~6.0 |

2.0~5.5 |

10~40 |

180*2 |

500 |

|

|

TM-168q |

φ60~φ168.3 |

1.5~5.0 |

60*60~130*130 |

1.5~4.5 |

10~50 |

180*2 |

400 |

|

TM-168 |

2.0~6.0 |

2.0~5.5 |

10~50 |

200*2 |

500 |

||

|

TM-168z |

φ76.2~φ168.3 |

2.5~8.0 |

2.5~7.0 |

10~40 |

200+132*2 |

600 |

|

|

TM-219q |

φ89.1~φ219.1 |

2.0~6.0 |

70*70~160*160 |

2.0~5.5 |

10~50 |

110*2+110*2 |

500 |

|

TM-219 |

3.0~8.0 |

3.0~7.0 |

10~40 |

132*2+132*2 |

600 |

||

|

TM-219z |

4.0~10.0 |

4.0~9.0 |

10~40 |

132*2+160*2 |

800 |

||

|

TM-273 |

φ114.3~φ273 |

4.0~10.0 |

90*90~200*200 |

4.0~9.0 |

10~40 |

160*2+160*2 |

800 |

|

TM-273z |

4.5~12.0 |

120*60~260*130 |

4.5~11.0 |

10~35 |

180*4 |

800 |

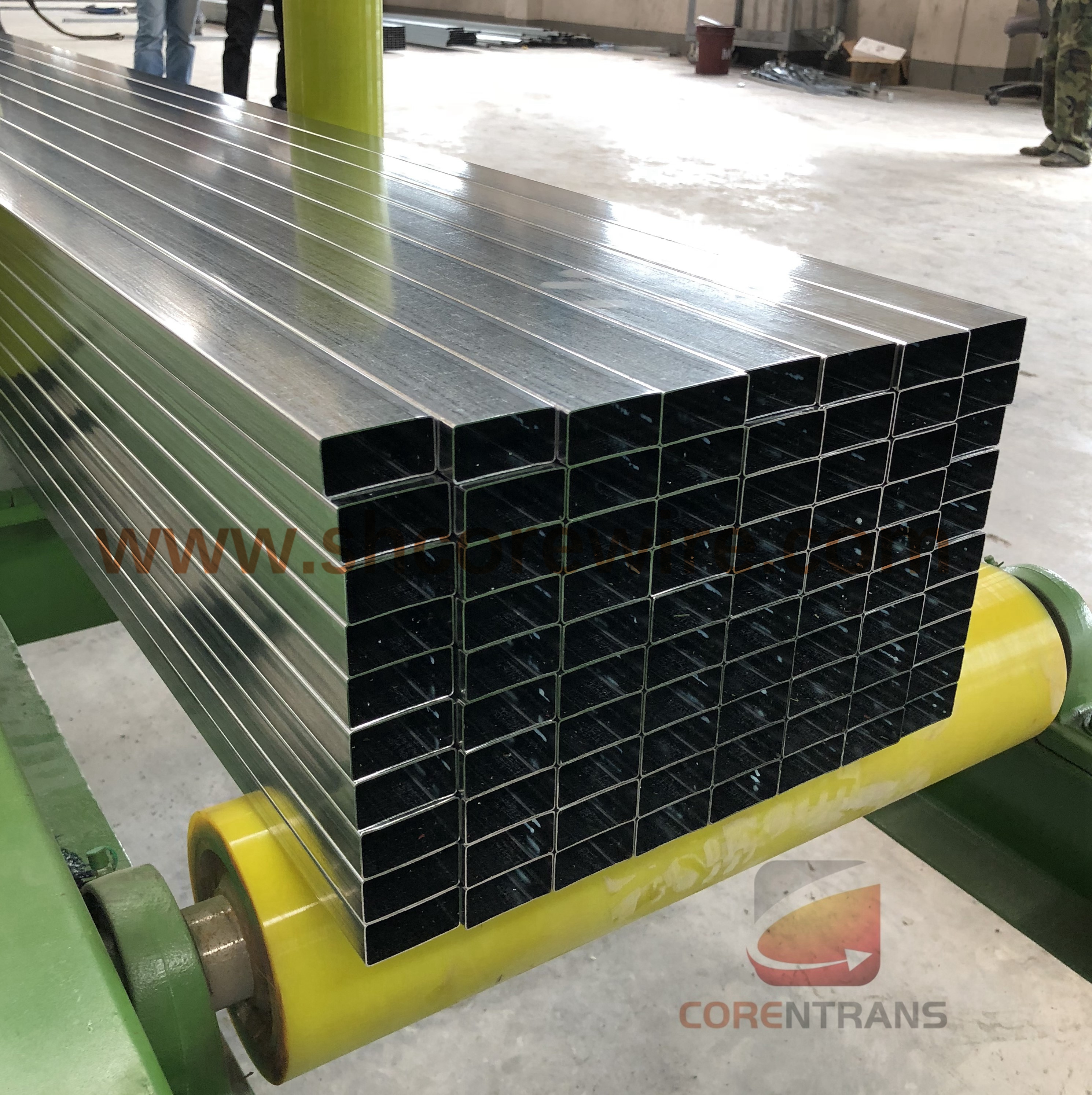

Application Display

Application:

The products are mainly pipes and tubes used in petroleum, petrochemical, construction, shipbuilding, car making, electric power, mining, coal, machinery manufacturing industries.

Product detail pictures:

Related Product Guide:

We usually continually offer you the most conscientious consumer services, along with the widest variety of designs and styles with finest materials. These initiatives include the availability of customized designs with speed and dispatch for OEM Customized Stainless Steel Tube Mills - High Frequency ERW Tube & Pipe Mill Machine – COREWIRE, The product will supply to all over the world, such as: Iraq, Manila, San Francisco, We have a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!

-

Newly Arrival Wet Wire Drawing Machine - Strai...

-

Rapid Delivery for Rewinder Group For Steel Wir...

-

Factory wholesale Corrugated Roll Forming Machi...

-

Factory wholesale Electrode Rods Furnace - Hig...

-

Factory source Ss Tube Mill - Cut to length li...

-

Top Suppliers Fully Automatic Nail Making Machi...