OEM Manufacturer High Quality Steel Tube - stainless-steel Industrial pipe making machine – COREWIRE Detail:

Applications: Mainly used for the production of stainless steel/carbon steel pipes/tubes with heavy thickness, which applied in decoration, furniture, hand Rail, outdoor decoration, household appliances industry, steel pipes/tubes etc.

Product Features:

High efficiency, less material waste

High yield rate, low production cost

Easy operation, continuous production

Durable machine, high precision, full automation

Introduction of product operation steps

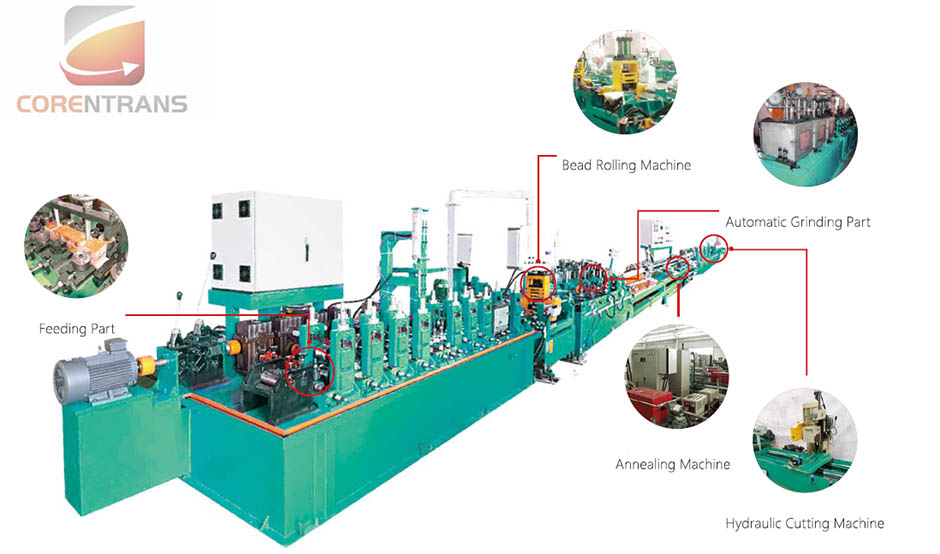

Stainless-less steel Pipe Making Machine flow chart

Uncoiler-Forming-Welding-Bead Rolling-Grinding-Staighten&Sizing1-Annealing-Straighten Sizing2-Eddy Current Testing-Cuting-Unload

Product introduction

Stainless-steel pipe making machine is mainly used for the continuous forming process of stainless steel and carbon steel profiles (a round tube, square pipe, special-shaped pipe, composite pipe), after unwinding, forming, argon-arc welding, welding grinding, sizing straightening, sizing cutting and other procedures. This process is characterized by continuous production, high efficiency, less material waste, and low production cost.

Introduction to product application

Common applications for stainless steel pipe include:

Case presentation

The main uses of finished products of Stainless steel industrial pipe making machine:

1、Automobiles: exterior parts, hot installation parts

2、Kitchen equipment: washing sink, gas stove, refrigerator

3、Steel pipes: decorative pipes, construction pipes, exhaust pipes

4、Chemical equipment: heat exchanger tubes, chemical industry stoves

5、Transportation equipment: containers, railroad cars

6、Electrical appliances: washing machines, dryers, microwave ovens, etc.

Product application scenario Display

Product parameters and model

|

Model |

Horizontal shaft |

Vertical shaft |

Diameter |

Thickness |

Motor power |

Grinding head |

Turkish head |

Main Engine Size(mm) |

|

ST40 |

φ40mm |

φ25mm |

φ9.5~φ50.8mm |

0.21~3.0mm |

7.5KW*2 |

3*3KW |

2PCS |

7600*1150 |

|

ST50 |

φ50mm |

φ30mm |

φ25.4~φ76mm |

0.3~3.5mm |

11KW*2 |

3*3KW |

2PCS |

9000*1200 |

|

ST60 |

φ60mm |

φ40mm |

φ50.8~φ114mm |

0.5~4.0mm |

15KW*2 |

3*4KW |

2PCS |

11000*1500 |

|

ST80 |

φ80mm |

φ50mm |

φ89~φ159mm |

1.0~5.0mm |

22KW*2 |

3*5.5KW |

2PCS |

12900*2100 |

|

ST100 |

φ100mm |

φ70mm |

φ114~φ273mm |

1.0~6.0mm |

30KW*2 |

3*5.5KW |

3PCS |

14000*2300 |

Product detail pictures:

Related Product Guide:

Using a full scientific good quality administration system, very good quality and superior faith, we win good standing and occupied this discipline for OEM Manufacturer High Quality Steel Tube - stainless-steel Industrial pipe making machine – COREWIRE, The product will supply to all over the world, such as: Indonesia, Yemen, USA, Our company absorbs new ideas, strict quality control, a full range of service tracking, and adhere to make high-quality solutions. Our business aims to "honest and trustworthy, favorable price, customer first", so we won the trust of the majority of customers! If you are interested in our items and services, please do not hesitate to contact us!

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.

-

Hot Selling for C Channel Roll Forming Machine ...

-

Chinese wholesale Sigma Purlin Roll Forming Mac...

-

Factory Price Decoiling Slitting Line - Automa...

-

Factory Cheap Hot Tube Mill Manufacturer - Aut...

-

Manufacturer for Tube Mill Rolls - High Freque...

-

Reliable Supplier Tube Forming Mill - Automati...