OEM manufacturer Stainless Steel Tube Mill Manufacturer - Cut to length line – COREWIRE Detail:

Introduction of product operation steps

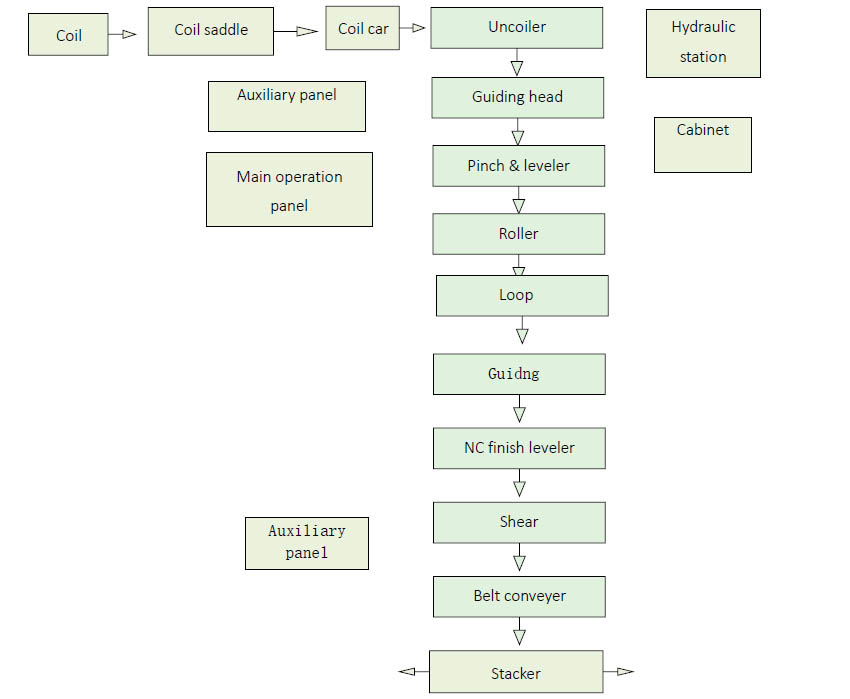

This line is composed of coil car, double support uncoiled, hydraulic pressing and guiding, shovel head, pre-leveler, finish leveler, cut to length machine, stacker, accompany electric control system, hydraulic system, etc. as well as pendulum middle plate, steering device.

Working Process

1. High degree of automation, easy & reliable operation

2. High length precision, high sheet flatness

This line is composed of coil car, double support uncoiled, pre-leveler, finish-leveler, length gauge, cut to length machine, stacker, servo driven system, etc. as well as pendulum middle bridge, pressing and guiding device and steering device.

This series line is used for HR coil(0.5mm-25mm) with different specifications, through uncoiling-leveling-cut to length to flattened plate as needed length.

Main technical parameter

Product detail pictures:

Related Product Guide:

We always get the job done to be a tangible staff to ensure that we can easily offer you the best high-quality and the greatest value for OEM manufacturer Stainless Steel Tube Mill Manufacturer - Cut to length line – COREWIRE, The product will supply to all over the world, such as: Croatia, United States, Moldova, Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. We can provided good quality with competitive price for you.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.

-

Wholesale Dealers of Nail Making Equipment - H...

-

Best Price on Corrugated Sheet Making Machine -...

-

High reputation Steel Tube Mill For Sale - Cut...

-

Reasonable price Cold Saw For Tube Mill - Auto...

-

Personlized Products Pc Steel Wire Stable Produ...

-

OEM Manufacturer Best Barbed Wire Making Machin...