Popular Design for Shutter Roll Forming Machine – Corrugated Roll Forming Machine – COREWIRE Detail:

Main Character

♦ Completely automatic cutting.

♦ Easy installation, good performance.

♦ Low noise, high efficiency.

Introduction of product operation steps

Hydraulic de-coiler → roll forming → hydraulic punching (2sets) → cutting →curing machine → product

Product introduction

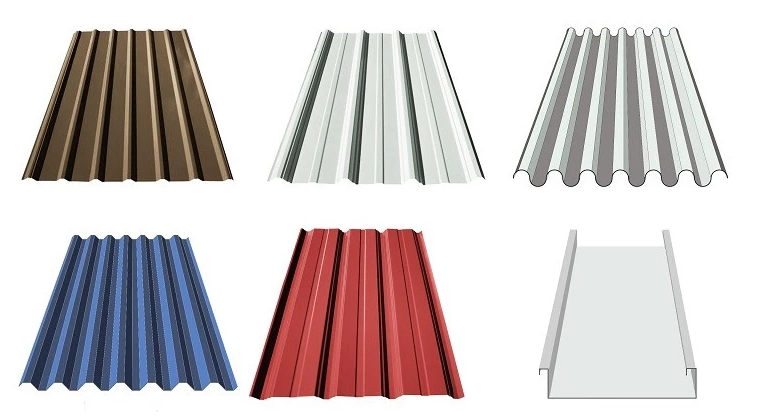

This Corrugated roll forming machine can produce corrugated metal tiles for industrial and civil buildings, warehouses, special buildings, large span steel roofs, house walls and exterior decoration, etc. It also includes some villages, supermarkets, hotels, exhibition halls, home buildings, shopping mall shutters and other buildings. Corrugated roll forming machine, roofing tile surface is very smooth and beautiful, the roof is not scratched. It has beautiful, external, classical appearance and elegant taste. We supply the best machine for our customer.

We have dozens of profile model machines for this series of molding, and we can design various profiles and accessories according to customers’ requirements.

Product parameters

| No | Item | Description |

| 1 | Material thickness | 0.3-0.8mm/ 2-4mm |

| 2 | Forming speed | 12-15m/min / 25-30m/min /15m/min |

| 3 | Roll station | 18 stations |

| 4 | Main power | 5.5KW/ 7.5KW/ 37KW |

| 5 | Hydraulic power | 3KW/ 7.5KW |

| 6 | Control system | PLC Panasonic |

| 7 | Drive | By Chain/ by gear box |

Main Technical Specification

| Material thickness: 0.3-0.8mm | Material thickness: 0.3-0.8mm | Material thickness:2-4mm |

| Working speed: 12-15m/min | Working speed: 25-30m/min | Working speed: 15m/min |

| Roll station: 18 stations (depend on the profile) | Roll station: 18 stations (depend on the profile) | Roll station: 18 stations (depend on the profile) |

| Main power: 5.5KW | Main power: 7.5KW | Main power: 37KW |

| Hydraulic power: 3KW | Hydraulic power: 3KW | Hydraulic power: 7.5KW |

| Control system: PLC Panasonic | Control system: PLC Panasonic | Control system: PLC Panasonic |

| Drive: by chain | Drive: by chain | Drive: by gear box |

Related products

Product detail pictures:

Related Product Guide:

We're going to commit ourselves to giving our esteemed buyers using the most enthusiastically considerate solutions for Popular Design for Shutter Roll Forming Machine – Corrugated Roll Forming Machine – COREWIRE, The product will supply to all over the world, such as: Riyadh, New York, Jamaica, We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The products to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they're created scientifically of purely raw supplies. It readily available in a variety of designs and specifications for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.

-

Fixed Competitive Price Cut To Length Steel - ...

-

Good User Reputation for Water Gutter Roll Form...

-

Discountable price Tube Mill Welding - High Fr...

-

Competitive Price for Wire Drawing Dead Block -...

-

Special Price for Wire Line Drawing Machine - ...

-

Wholesale Corrugated Roof Panel Roll Forming Ma...