Professional Design Tube Roll Forming Machine - Wheelbarrow Production Line – COREWIRE Detail:

CWE-1600 METAL SHEET Embossing Machine

Model No.: CWE-1600

Introduction:

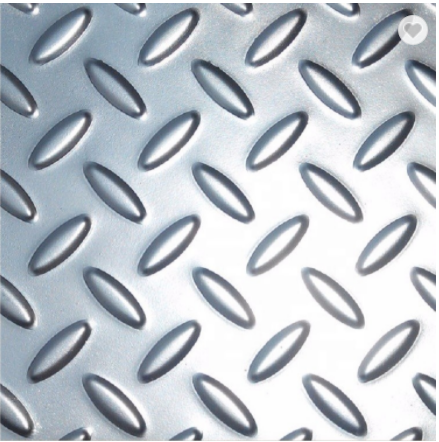

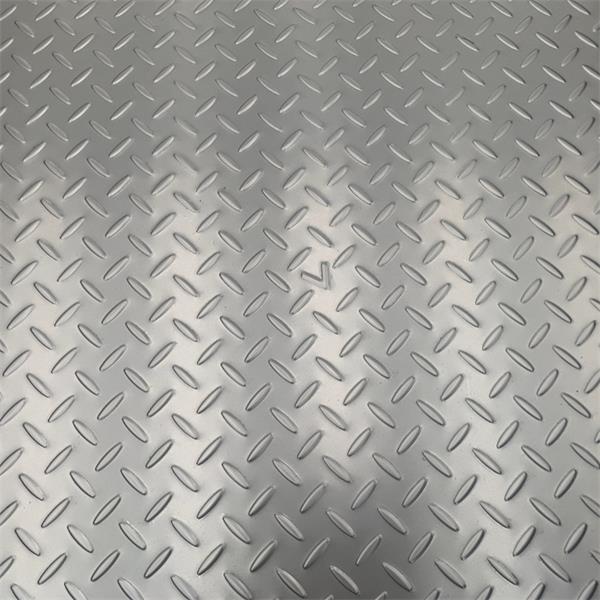

Metal embossing machines are mainly for producing embossed aluminum and stainless metal sheets. metal embossing production line is suitable for metal sheet, particle board, decorated materials, and so on. The pattern is clear and has strong third-dimension. It can be assorted with the embossing production line. Metal sheet embossing machine for anti-slip floor embossed sheet could be used to make various type anti-slip sheets for many various functions.

Simple operation: Feed platform- Output conveyor table

CNC Precision Carved Roller:

We have adopted quality alloy steel (special steel for roller) to forge the roller, which enhance the rigidity and toughness.

Machine type: Reduce adjustment embossing, convenient and easy, stable and reliable.

Application: Metal sheet embossing of aluminum, copper, color steel, steel, stainless steel, etc.

Metal Embossing plate has many advantages such as beautiful appearance, anti-slip, strengthening performance and steel saving. It is widely used in the fields of transportation, construction, decoration, base plate around equipment, machinery, shipbuilding, etc.

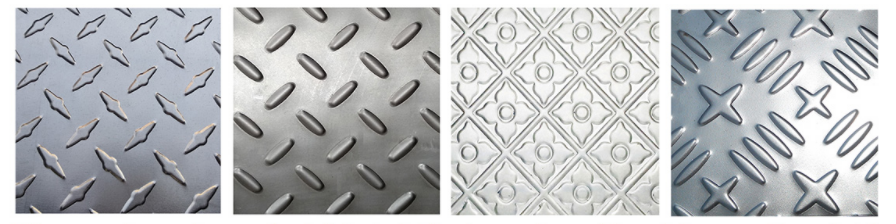

More than 30 kinds of decorative pattern to choose, the patterns also can design according to customer requirements.

Sample Plate:

We have professional engineers who will design the logo on pattern according to the pattern chosen by the customer.

Ⅰ、CWE1600 Embossing Machine Parameter:

| Outer size | 3600×1200×1700mm |

| Roller specification | Φ420-430×1600mm |

| Roller pattern | Willow leaf |

| Roller material | Superior alloy steel (China Code 42CrMo) forged roller |

| Embossing type | Both up and down rollers embossing at same time |

| Motor | 380V 11Kw 50Hz Siemens motor with reducer |

| Embossing regulation | By Worm gear reducer |

| Transmission | By Gear |

| Line Speed | 0-25m/min |

| Thickness of plate | 1-2×1500mm steel plate |

| Type | Fully automatic |

| Usage | Embossing pattern |

| Function | Embossing on metal |

We will test the machine before delivery, send the test video and photos to the customer for confirmation, and support third-party institutions to inspect the goods.

Product detail pictures:

Related Product Guide:

In order to best meet client's needs, all of our operations are strictly performed in line with our motto "High Quality, Competitive Price, Fast Service" for Professional Design Tube Roll Forming Machine - Wheelbarrow Production Line – COREWIRE, The product will supply to all over the world, such as: Libya, venezuela, Melbourne, Facing fierce global market competition, we have launched the brand building strategy and updated the spirit of "human-oriented and faithful service", with an aim to gain global recognition and sustainable development.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.

-

Factory Cheap Hot Tube Mill Manufacturer - Aut...

-

2021 Good Quality Tube Mill Line - Cut to leng...

-

OEM/ODM Factory Automatic Barbed Wire Fence Mac...

-

OEM Customized Stainless Steel Tube Mills - Au...

-

Factory wholesale Tube Mill High Frequency Weld...

-

New Arrival China Cz Interchangeable - Guard R...