Renewable Design for Roof Panel Roll Forming Machine - High Speed Roofing Panel Roll Forming Machine – COREWIRE Detail:

Introduction of product operation steps

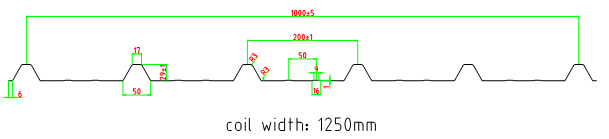

Profile drawing:

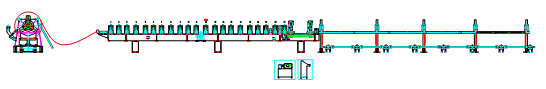

The chart of process flow:

10T Hydraulic Uncoiler—Roll Forming—Track cutting—Auto stacker

Product parameters

| 1 | Coil width | 1250mm |

| 2 | Rolling Speed | 0-35m/min |

| 3 | Rolling Thickness | 0.3-0.8mm |

| 4 | Control System | PLC (Panasonic) as list in the note |

| 5 | Un Coiler | 5T hydraulic de-coiler |

| 6 | Roller Stations | 20 stations |

| 7 | Roller Material | ASTM1045 chrome plated surface with chrome |

| 8 | Shaft Material and DIA | ¢76mm material:45# with quenching and tempering |

| 9 | Post track cutting | The main machine won’t stop when cutting, 2.9kw servo motor |

| 10 | Maim Motor Power | 15kw |

| 11 | Hydraulic Station Power | 5.5kw with storage tank and air cooling system |

| 12 | Hydraulic Pressure | 12-16Mpa adjustable |

| 13 | Material Of Cutting | CR12with heat treatment |

| 14 | Structure Of The Stations | Iron cast |

| 15 | Tolerance | 3m+-1.5mm |

| 16 | Electric Source | 380V, 50HZ,3 phaseAccording to customer’s require |

| 17 | Way Of Drive | By gear box |

Related products

Packaging & Delivery

Packaging Details:

Roofing Panel Roll Forming Machine

1. The machine is nude loaded in the container

2. The electric controlling box is packed by protect film

3. All the spare parts are put in the wooden box

Product detail pictures:

Related Product Guide:

Our mission should be to turn out to be an innovative supplier of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and repair capabilities for Renewable Design for Roof Panel Roll Forming Machine - High Speed Roofing Panel Roll Forming Machine – COREWIRE, The product will supply to all over the world, such as: Serbia, Milan, Colombia, As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality products and solutions we supply, effective and satisfying consultation service is supplied by our professional after-sale service group. Solution lists and thorough parameters and any other info weil be sent for you timely for the inquiries. So make sure you get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We're confident that we have been going to share mutual results and build solid co-operation relations with our companions in this market. We're looking forward to your inquiries.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.

-

Cheapest Price Nail Making Machine For Sale - ...

-

China Supplier Steel Door Frame Roll Forming Ma...

-

Discount Price Steel Leveling Machine - High Q...

-

China wholesale Straight Line Wire Drawing Mach...

-

Good Wholesale Vendors Nail Making For Sale - ...

-

High Quality for Metal Roofing Tiles Roll Formi...