Trending Products Deck Floor Roll Forming Machine - High Speed Roofing Panel Roll Forming Machine – COREWIRE Detail:

Introduction of product operation steps

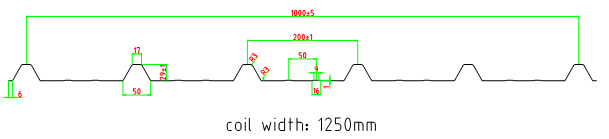

Profile drawing:

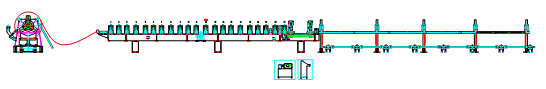

The chart of process flow:

10T Hydraulic Uncoiler—Roll Forming—Track cutting—Auto stacker

Product parameters

| 1 | Coil width | 1250mm |

| 2 | Rolling Speed | 0-35m/min |

| 3 | Rolling Thickness | 0.3-0.8mm |

| 4 | Control System | PLC (Panasonic) as list in the note |

| 5 | Un Coiler | 5T hydraulic de-coiler |

| 6 | Roller Stations | 20 stations |

| 7 | Roller Material | ASTM1045 chrome plated surface with chrome |

| 8 | Shaft Material and DIA | ¢76mm material:45# with quenching and tempering |

| 9 | Post track cutting | The main machine won’t stop when cutting, 2.9kw servo motor |

| 10 | Maim Motor Power | 15kw |

| 11 | Hydraulic Station Power | 5.5kw with storage tank and air cooling system |

| 12 | Hydraulic Pressure | 12-16Mpa adjustable |

| 13 | Material Of Cutting | CR12with heat treatment |

| 14 | Structure Of The Stations | Iron cast |

| 15 | Tolerance | 3m+-1.5mm |

| 16 | Electric Source | 380V, 50HZ,3 phaseAccording to customer’s require |

| 17 | Way Of Drive | By gear box |

Related products

Packaging & Delivery

Packaging Details:

Roofing Panel Roll Forming Machine

1. The machine is nude loaded in the container

2. The electric controlling box is packed by protect film

3. All the spare parts are put in the wooden box

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Trending Products Deck Floor Roll Forming Machine - High Speed Roofing Panel Roll Forming Machine – COREWIRE, The product will supply to all over the world, such as: Luxembourg, Norway, Armenia, We have been persisting in the business essence "Quality First, Honoring Contracts and Standing by Reputations, providing customers with satisfying goods and service. " Friends both at home and abroad are warmly welcome to establish everlasting business relations with us.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,

-

Ordinary Discount Tube Mill Spare Parts - Auto...

-

Online Exporter High Speed Iron Wire Nail Makin...

-

Wholesale Price Electrode Rods E7018 - Straigh...

-

Super Lowest Price Tube Mill Production Line -...

-

OEM manufacturer Automatic Nail Making Machine ...

-

High reputation Roofing Wall Panel Roll Forming...