Trending Products Deck Floor Roll Forming Machine - Metal Deck Roll Forming Machine – COREWIRE Detail:

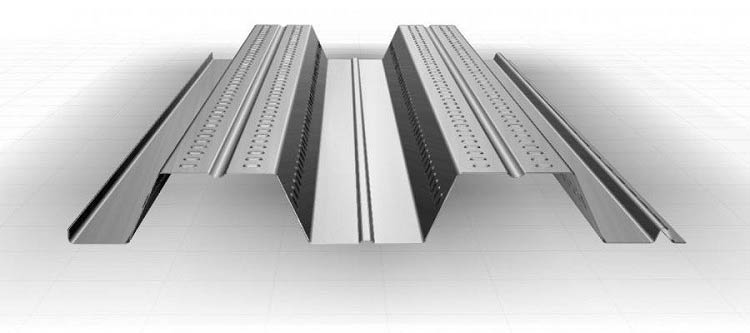

Metal Deck Roll Forming Machine is a color-coated steel plate that is cold-rolled into various wave-shaped pressed plates. It is suitable for industrial and civil buildings, warehouses, special buildings, roofs, walls and interior and exterior wall decoration of large-span steel structures. It has the characteristics of light weight, high strength, rich color, convenient and quick construction, anti-seismic, fireproof, rainproof, long life and maintenance-free. It has been widely used.

Introduction of product operation steps

This Metal Deck Roll Forming Machine has high strength and large wave width. It bonds well with concrete and it is used in high-rise buildings. It not only saves steel plate formwork, but also saves investment. Deck floor panel is used for high-rise building panel, which has many advantages such as high volatility, high strength, high atomization and low cost.

1、In the use stage floor bearing plate as the concrete floor slab of the tensile steel, also improves the stiffness of the floor slab, saving the amount of steel and concrete.

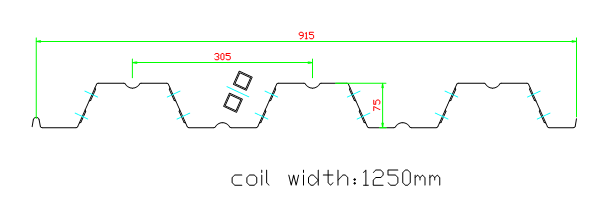

2、The surface embossing of the pressed plate makes the maximum bonding force between the floor bearing plate and concrete, so that the two form a whole, with stiffening ribs, so that the floor bearing plate system has high bearing capacity.

Profile drawing

A floor bearing plate is a pressed and formed steel plate used to support concrete for floors and is known as a profiled steel plate. It is widely used in power plants, power equipment companies, automobile showrooms, steel workshops, cement warehouses, steel offices, airport terminals, railway stations, stadiums, concert halls, grand theaters, hypermarkets, logistics centers and the Olympic Games. Steel buildings, such as gymnasiums and stadiums.

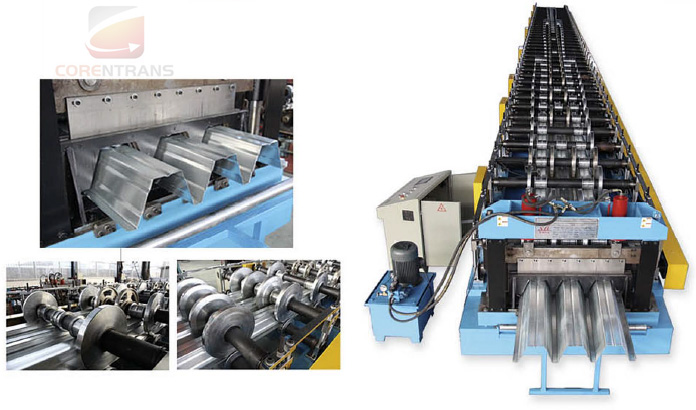

The equipment runs stably, the operation is simple, the processing procedure is fine and complex. Lightweight structure, reasonable design, insist on serving customers with high quality products.

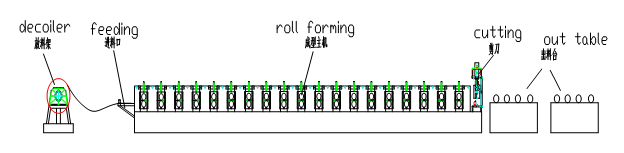

The chart of process flow:

Applications

Product parameters

| No. | Item | Description |

| 1 | Machine structure | Wall board structure |

| 2 | Total power | Motor power-11kw x2Hydraulic power-5.5kw |

| 3 | Roller stations | About 30 stations |

| 4 | Productivity | 0-15m/min( excluding cutting time) |

| 5 | Drive system | By chain |

| 6 | Diameter of shaft | ¢85mm solid shaft |

| 7 | Voltage | 380V 50Hz 3phases (Customized) |

| 8 | Container need | 40HQ container |

Related products

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Trending Products Deck Floor Roll Forming Machine - Metal Deck Roll Forming Machine – COREWIRE, The product will supply to all over the world, such as: Benin, Mauritania, UAE, Our business activities and processes are engineered to make sure our customers have access to widest range of products with the shortest supply time lines. This achievement is made possible by our highly skilled and experienced team. We look for people who want to grow with us around the globe and stand out from the crowd. We now have people who embrace tomorrow, have vision, love stretching their minds and going far beyond what they thought was achievable.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.

-

factory Outlets for Steel Coil Cutting Machine ...

-

Best quality Electrode Rods Oven - High Qualit...

-

Chinese wholesale Wire Drawing Machine Price -...

-

2021 Good Quality Purlin Roll Forming Machine F...

-

Special Design for Cut To Length Line Supplier ...

-

2021 wholesale price Wire Drawing Machine - Hi...