Well-designed Corrugated Iron Roofing Sheet Making Machine - Guard Rail Roll Forming Machine – COREWIRE Detail:

Guard rail roll forming machine is used to produce guard rails or crash barriers. Hot rolled, galvanized or other steel sheet and coil is suitable roll forming materials for this machine. This machine is mainly made up of loading coil car, exit looping kit, roll former with tooling, automatic stacking device, flying cut-off machine, servo roll feeder, leveler, loading coil car, etc. The finished products are widely used on highway, expressway and other public places to prevent different kinds of accidents and improve safety. They can also be used as fence for livestock farms and other places.

Features

1. This production line can be automatically run by inputting some data (like products length and batches) to the PLC control system.

2. Very strong base frame is configured to avoid vibration.

3. All the rollers have been processed by CNC lathe and polished on the surface to guarantee the accuracy.

4. The rollers have gone through hardened treatment to guarantee long lifespan.

5. We can also design the crash barrier roll forming machine according to customer’s requirement.

Forming Processing

Hydraulic decoiler – Leveling – Feeding – Punching – Conveyor – Roll forming – Auto Stacker

Introduction

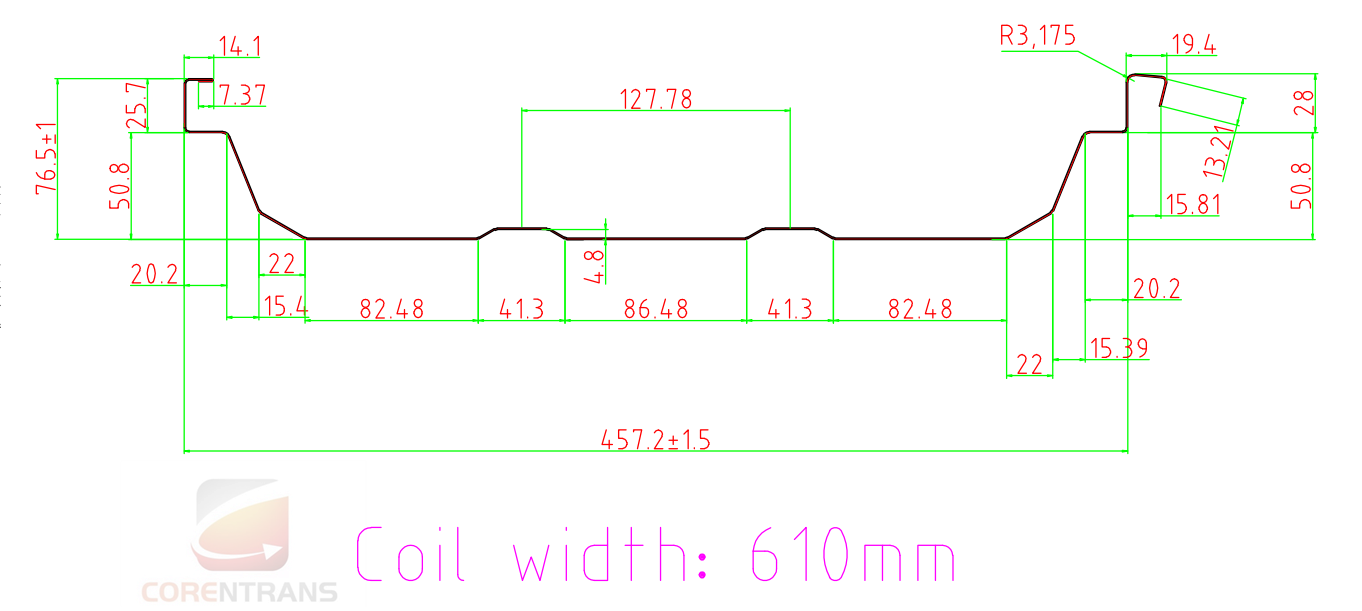

Profile drawing:

| No. | Specification of the material | |

| 1 | Suitable Material | PPGI 345Mpa |

| 2 | Width of the raw material | 610mm and 760mm |

| 3 | Thickness | 0.5-0.7mm |

Product parameters

|

No |

Item | Description |

|

1 |

Machine structure | Wire-electrode cutting frame |

|

2 |

Total power | Motor power-7.5kw Siemens Hydraulic power-5.5kw Siemens |

|

3 |

Roller stations | About 12 stations |

|

4 |

Productivity | 0-20m/min |

|

5 |

Drive system | By chain |

|

6 |

Diameter of shaft | ¢70mm solid shaft |

|

7 |

Voltage | 415V 50Hz 3phases (Customized) |

Related products

Product detail pictures:

Related Product Guide:

Our advantages are lower prices,dynamic sales team,specialized QC,strong factories,high quality products and services for Well-designed Corrugated Iron Roofing Sheet Making Machine - Guard Rail Roll Forming Machine – COREWIRE, The product will supply to all over the world, such as: Madagascar, Maldives, Montpellier, We welcome you to visit our company, factory and our showroom displayed various products that will meet your expectation, meanwhile, it is convenient to visit our website, our sales staff will try their efforts to offer you the best service. If you need to have more information, remember to do not hesitate to contact us by E-mail or telephone.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!

-

Excellent quality Corrugated Steel Panel Roll F...

-

Hot New Products Roll Forming Machine For C Pur...

-

High Quality C Purlin Forming Machine - C/Z Pu...

-

Big discounting Saw Blade Grinding Machine For ...

-

Professional China Straight Line Wire Drawing M...

-

Best Price on Steel Coil Slitting Machine - Cu...